G-Code is a numerical code standard for CNC machining‚ translating commands into mechanical actions using G and M codes for precise movements and operations‚ essential.

What is G-Code?

G-Code is a numerical programming language used to control CNC (Computer Numerical Control) machines. It consists of G-codes for movements and actions‚ and M-codes for machine functions. Each code instructs the machine to perform specific tasks‚ such as moving to a location‚ turning the spindle on‚ or enabling coolant. G-Code is widely used in manufacturing to program precise cutting‚ drilling‚ and milling operations. It is often provided in PDF guides for quick reference‚ making it easier for operators to understand and implement complex machining processes. These guides compile essential commands‚ ensuring efficient and accurate CNC operations across industries.

Importance of G-Code in CNC Machining

G-Code is essential for CNC machining as it enables precise and efficient control of machine tools. By providing detailed instructions‚ it ensures accurate cuts‚ drills‚ and finishes. This language is universal‚ allowing compatibility across different CNC controllers. Its importance lies in reducing human error‚ increasing productivity‚ and enabling complex designs. A G-Code list PDF serves as a valuable resource‚ compiling commands for quick reference. This ensures operators can execute tasks confidently‚ knowing each code’s function. Additionally‚ G-Code’s versatility supports various industries‚ from automotive to aerospace‚ making it indispensable in modern manufacturing. Its role in automation and precision underscores its critical importance in CNC operations globally.

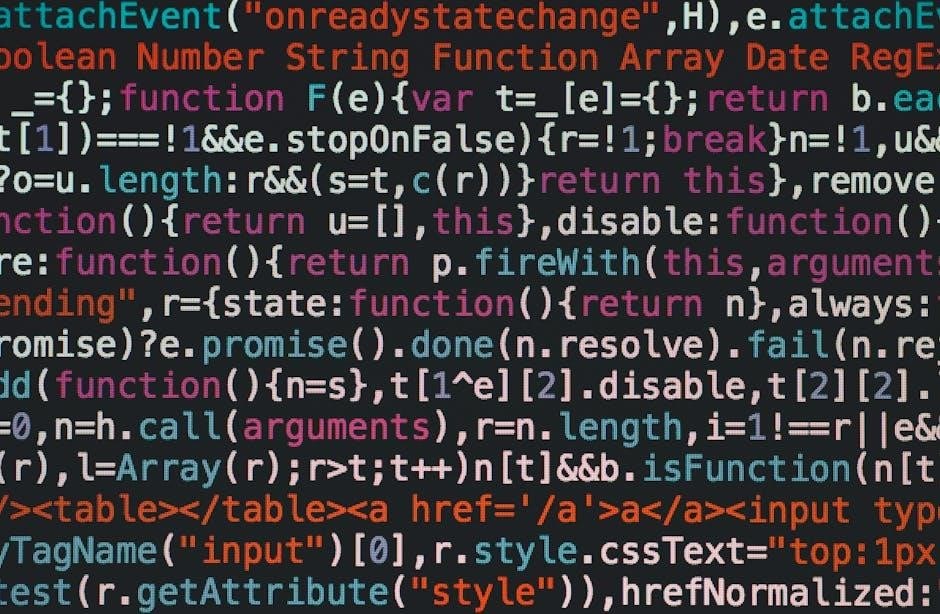

Basic Structure of G-Code Commands

G-Code commands follow a structured format‚ typically starting with a letter (e.g.‚ G or M) followed by a numerical code. Commands are modular‚ allowing for combinations to achieve specific tasks. Each line can include multiple fields‚ such as coordinates‚ feed rates‚ or spindle speeds‚ separated by spaces or line breaks. For example‚ G00 X10 Y20 F100 moves the tool quickly to coordinates (10‚20) at a feed rate of 100. Parameters like S1200 (spindle speed) or T05 (tool selection) enhance functionality. Comments‚ often preceded by parentheses‚ provide clarity without affecting execution. This structured format ensures precision and consistency in CNC machining‚ making G-Code lists in PDF invaluable for quick reference and programming efficiency.

Essential G-Code Commands

G00 sets rapid positioning‚ moving tools quickly without cutting. G01 executes linear interpolation for precise cutting paths. M03 starts spindle rotation clockwise‚ while M05 stops it‚ ensuring safe operations and efficient machining workflows.

G-Code Commands for Movement

G-Code commands for movement are essential for positioning tools and workpieces accurately. G00 is used for rapid positioning‚ moving tools quickly without cutting. G01 performs linear interpolation‚ guiding tools along precise paths during cutting operations. G02 and G03 handle circular interpolation‚ respectively for clockwise and counterclockwise movements. G17 sets the XY-plane for arc commands‚ while G21 ensures measurements are in millimeters. G54 selects the first coordinate system‚ and G28 returns the tool to its home position. These commands enable precise control over machine movements‚ ensuring accurate and efficient machining processes. Proper use of these codes is critical for achieving desired results in CNC operations.

G-Code Commands for Feed Rate and Spindle Control

G-Code commands for feed rate and spindle control manage machine speed and rotation. G93 sets feed rate per minute‚ while G94 sets it per revolution. M03 starts spindle rotation clockwise‚ and M04 rotates counterclockwise. M13 combines spindle start and feed rate for tapping. S### specifies spindle speed in RPM‚ and F### defines feed rate in units per minute. These commands ensure precise control over machining speeds‚ optimizing material removal rates and tool longevity. Proper use of these codes is vital for achieving high-quality finishes and maintaining equipment efficiency in CNC operations. They allow for dynamic adjustments during machining cycles‚ ensuring optimal performance.

G-Code Commands for Coolant Control

G-Code commands for coolant control manage the activation and deactivation of coolant systems during machining. M08 turns on coolant‚ typically flood coolant‚ while M09 turns it off. M07 activates mist coolant for precision applications. These commands ensure proper lubrication and cooling‚ preventing overheating and improving surface finish. Coolant control is critical for maintaining tool life and achieving accurate cuts. Proper use of these codes ensures efficient machining operations‚ reducing thermal damage and extending equipment longevity. They are essential for maintaining optimal cutting conditions in CNC machining processes. Always refer to a G-Code list PDF for specific controller variations and capabilities. Proper implementation enhances overall machining performance and product quality.

G-Code Parameters and Modal Commands

G-Code parameters define values for commands‚ while modal commands remain active until changed. Parameters set variables like feed rates‚ and modal commands control machine states‚ such as spindle modes. A G-Code list PDF details standard parameters and modal commands‚ ensuring compatibility across CNC controllers. Proper use enhances programming efficiency and consistency. Always consult a G-Code reference guide for specific implementations and variations. This ensures accurate and reliable machining operations. Modal commands simplify programming by maintaining settings until explicitly modified. Parameters and modals work together to streamline CNC operations. Refer to a G-Code list PDF for comprehensive details and controller-specific instructions. This resource is invaluable for optimizing G-Code programming and achieving precise results. Understanding parameters and modals is crucial for mastering G-Code and improving machining efficiency. They allow for dynamic adjustments and consistent operation‚ reducing errors and downtime. A G-Code list PDF provides a quick reference for these essential elements‚ ensuring accurate programming and machine performance. Parameters and modal commands are fundamental to creating efficient and effective G-Code programs. They enable precise control over machining operations‚ ensuring high-quality outcomes. Always verify parameters and modals in a G-Code list PDF for your specific CNC controller to maintain consistency and accuracy. This approach guarantees optimal performance and minimizes potential issues during machining. Parameters and modal commands are essential tools for any CNC programmer‚ offering flexibility and control. A G-Code list PDF is an indispensable resource for mastering these elements and improving overall machining operations. By leveraging parameters and modals effectively‚ programmers can create sophisticated and efficient G-Code programs tailored to their needs.

Understanding Modal and Non-Modal Commands

Modal commands in G-Code remain active until explicitly canceled or modified‚ while non-modal commands execute once and do not persist. For example‚ modal commands like G81 (drilling cycle) stay active until replaced by another cycle command. Non-modal commands‚ such as G00 (rapid positioning)‚ execute immediately without lasting effects. Understanding the difference is crucial for efficient programming‚ as modal commands reduce repetitive code and streamline operations. A G-Code list PDF provides detailed explanations and examples‚ helping programmers avoid errors. Modal commands are particularly useful for repetitive tasks‚ while non-modal commands offer precision for one-time operations. Proper use enhances program clarity and machine performance. Always consult a G-Code reference guide for specific implementations and best practices. This ensures accurate and reliable machining results. Modal and non-modal commands are fundamental to G-Code programming‚ and mastering their use is essential for achieving optimal CNC performance. A G-Code list PDF is an invaluable resource for this purpose‚ offering clear guidelines and examples to improve programming skills. By understanding these command types‚ programmers can create efficient‚ error-free G-Code programs tailored to their machining needs.

Using Parameters in G-Code Programming

Parameters in G-Code are variables used to store and reuse values‚ enhancing program flexibility. They are often used for tool offsets‚ feed rates‚ and spindle speeds. For example‚ G54 sets a work offset‚ while T01 selects a tool with predefined parameters. A G-Code list PDF provides detailed explanations of parameter codes and their functions. Parameters simplify customization of machining operations without altering the entire program. They reduce errors and improve efficiency by standardizing settings. Proper use of parameters ensures consistent results across different tools and materials. A G-Code list PDF is essential for understanding and applying these parameters effectively in CNC programming. Always refer to a reliable guide for accurate implementation. This ensures optimal machine performance and precise machining outcomes. Parameters are a cornerstone of advanced G-Code programming‚ enabling customization and repeatability in manufacturing processes. A G-Code list PDF offers comprehensive insights‚ making it an indispensable resource for programmers. By leveraging parameters‚ users can achieve higher productivity and accuracy in their CNC operations. This approach minimizes manual adjustments and streamlines the machining workflow. Parameters are a powerful tool in G-Code programming‚ and understanding their application is vital for achieving professional results. A G-Code list PDF provides the necessary guidance to master their use. Parameters are essential for optimizing CNC operations and ensuring consistent‚ high-quality output. Always consult a G-Code reference guide to maximize their potential in your programming tasks. This ensures that all parameters are applied correctly and efficiently. Parameters are a key feature of G-Code‚ offering flexibility and precision in machining operations. A G-Code list PDF is the ultimate resource for mastering their use and improving overall programming skills. By utilizing parameters effectively‚ programmers can create sophisticated‚ efficient‚ and error-free G-Code programs for various CNC applications. This ensures that all machining operations are executed with precision and reliability. Parameters are a fundamental aspect of G-Code programming‚ and their proper use is critical for achieving outstanding results. A G-Code list PDF provides the necessary tools and knowledge to excel in this area. Always rely on a comprehensive guide to ensure optimal use of parameters in your G-Code programs. This guarantees that all machining operations are performed accurately and efficiently. Parameters are a vital component of G-Code programming‚ enabling customization and precision in CNC machining. A G-Code list PDF is an essential resource for programmers seeking to master their use. By understanding and applying parameters correctly‚ users can achieve superior results in their manufacturing processes. This ensures that all operations are executed with utmost accuracy and efficiency. Parameters are a cornerstone of advanced G-Code programming‚ and a G-Code list PDF is the perfect tool for unlocking their full potential. Always consult a reliable guide to ensure that parameters are used effectively in your programs. This guarantees that all machining operations are performed to the highest standards. Parameters are a powerful feature in G-Code‚ offering endless possibilities for customization and optimization. A G-Code list PDF provides the insights needed to harness their full potential. By mastering the use of parameters‚ programmers can create complex‚ efficient‚ and precise G-Code programs for any CNC application. This ensures that all machining operations are executed flawlessly and consistently. Parameters are a key element in G-Code programming‚ and their proper application is essential for achieving professional results. A G-Code list PDF is the ultimate resource for programmers seeking to excel in this field. Always refer to a comprehensive guide to ensure that parameters are used effectively in your programs. This guarantees that all machining operations are performed with precision and reliability. Parameters are a fundamental aspect of G-Code programming‚ enabling customization and efficiency in CNC machining. A G-Code list PDF is an invaluable resource for mastering their use. By understanding and applying parameters correctly‚ users can create sophisticated‚ error-free G-Code programs for various applications. This ensures that all operations are executed with accuracy and consistency. Parameters are a vital component of G-Code programming‚ and their proper use is critical for achieving outstanding results. A G-Code list PDF provides the necessary tools and knowledge to excel in this area. Always rely on a comprehensive guide to ensure optimal use of parameters in your G-Code programs. This guarantees that all machining operations are performed accurately and efficiently. Parameters are a cornerstone of advanced G-Code programming‚ enabling customization and precision in CNC machining. A G-Code list PDF is an essential resource for programmers seeking to master their use. By understanding and applying parameters correctly‚ users can achieve superior results in their manufacturing processes. This ensures that all operations are executed with utmost accuracy and efficiency. Parameters are a powerful feature in G-Code‚ offering endless possibilities for customization and optimization. A G-Code list PDF provides the insights needed to harness their full potential. By mastering the use of parameters‚ programmers can create complex‚ efficient‚ and precise G-Code programs for any CNC application. This ensures that all machining operations are executed flawlessly and consistently. Parameters are a key element in G-Code programming‚ and their proper application is essential for achieving professional results. A G-Code list PDF is the ultimate resource for programmers seeking to excel in this field. Always refer to a comprehensive guide to ensure that parameters are used effectively in your programs. This guarantees that all machining operations are performed with precision and reliability.

G-Code Subcodes and Functions

G-Code subcodes enhance functionality by modifying commands. They manage tool offsets‚ work coordinates‚ and auxiliary functions. A G-Code list PDF details these subcodes‚ aiding precise CNC operations and programming efficiency.

Subcodes for Tool Selection and Offset

G-Code subcodes for tool selection and offset enable precise tool management. Commands like G43 and G44 handle tool length offsets‚ ensuring accurate machining. A G-Code list PDF provides detailed explanations of these subcodes‚ helping programmers adjust tools dynamically. Proper use of these subcodes minimizes errors and optimizes machining processes. They are essential for maintaining consistency across different tools and operations‚ ensuring high-quality output in CNC machining. These subcodes are fundamental for efficient and accurate tool management in G-Code programming‚ making them a critical component of any CNC operation.

Subcodes for Work Offset and Coordinate Systems

G-Code subcodes for work offset and coordinate systems are crucial for precise machining. Commands like G54 to G59 define work offsets‚ allowing the machine to adjust the working area relative to the origin. These subcodes enable shifting the coordinate system‚ ensuring accurate part production. Additionally‚ codes like G90 and G91 control absolute and incremental positioning‚ respectively. A G-Code list PDF provides comprehensive details on these subcodes‚ helping programmers manage coordinate systems and offsets effectively. Proper use ensures consistent and accurate machining‚ making these subcodes indispensable for complex CNC operations. They simplify setup and enhance precision‚ streamlining the machining process for optimal results.

G-Code Syntax and Formatting

G-Code syntax and formatting involve structured commands‚ parameters‚ and line organization. Each line typically starts with a letter followed by numbers‚ defining actions and coordinates. Proper formatting ensures accurate CNC execution.

Line Structure and Command Separation

G-Code line structure follows a specific format‚ with each line representing a single command block. Commands are separated by spaces or specific characters‚ ensuring clarity for CNC interpretation. A typical line starts with a letter (e.g.‚ G or M) followed by numbers and parameters. For example‚ G00 X10 Y20 moves the tool to coordinates (10‚20). Commands within a line are separated logically‚ avoiding ambiguity. Proper line structure ensures smooth execution‚ while incorrect formatting can lead to machine errors. N numbers are optional and used for line labeling. Comments‚ enclosed in parentheses‚ provide clarity without affecting execution. Consistent formatting is critical for reliable CNC operation.

Comment Lines and Block Delete

Comment lines in G-Code are enclosed in parentheses and provide descriptive notes for the programmer. These lines are ignored by the CNC machine‚ making them useful for clarity. For example‚ (This is a comment) explains the purpose of a command. Block delete‚ using the slash / at the start of a line‚ skips execution of that line. This feature is handy for testing or modifying code without deleting lines. Proper use of comments and block deletes enhances readability and reduces errors. They are essential tools for organizing and debugging G-Code programs‚ ensuring smooth CNC operations and accurate machining results. Always follow syntax rules for these features to avoid conflicts or misinterpretation.

G-Code List PDF Resources

G-Code list PDFs are essential for quick reference‚ providing detailed command overviews and practical examples. They are widely available online‚ offering comprehensive guides for CNC machining.

Why Use a G-Code List in PDF Format?

A G-Code list in PDF format is a valuable resource for CNC machinists‚ offering a portable and easily accessible reference guide. PDFs maintain consistent formatting across devices‚ ensuring clarity. They are ideal for quick lookups‚ reducing downtime during production. Additionally‚ PDF guides often include visual diagrams and examples‚ enhancing understanding. Many resources are free or affordable‚ making them accessible to hobbyists and professionals alike. PDFs are also searchable‚ allowing users to find specific commands quickly. This format is universally compatible‚ working on computers‚ tablets‚ and smartphones. Overall‚ a G-Code list in PDF format streamlines workflow‚ improves efficiency‚ and serves as an essential tool for CNC programming.

Popular Sources for G-Code PDF Guides

Several reputable sources provide comprehensive G-Code PDF guides‚ catering to both beginners and experienced machinists. CNC machine manufacturers like Haas‚ Fanuc‚ and Siemens often publish detailed G-Code reference guides specific to their controllers. Online forums and communities‚ such as CNCzone or Reddit‚ frequently share user-contributed PDF resources. Educational institutions and training centers also offer G-Code PDF materials as part of their curriculum. Additionally‚ websites like Instructables‚ Coursera‚ and Udemy provide free or paid downloadable guides. These sources ensure access to standardized and controller-specific G-Code information‚ helping machinists optimize their programming skills. Always verify the source for accuracy and compatibility with your CNC system.

Best Practices for G-Code Programming

- Use consistent formatting for readability.

- Incorporate comments to explain complex operations.

- Validate code with simulations before execution.

- Optimize tool paths to reduce machining time.

- Adhere to machine-specific G-Code standards.

Common Mistakes to Avoid

When working with G-Code‚ common mistakes include incorrect syntax‚ forgotten units‚ and improper zero offsets. Forgetting to set the correct coordinate system (inch vs. mm) can lead to scaling errors. Another mistake is neglecting to include a safety clearance before cutting‚ which can result in tool or workpiece damage. Additionally‚ programmers often overlook enabling coolant or spindle commands‚ causing overheating or poor finish. Incorrect feed rates or tool offsets can damage tools or produce inaccurate parts. Always verify G-Code with simulation software before machining to catch errors early. Adhering to these guidelines ensures safer and more efficient CNC operations.

Optimizing G-Code for CNC Machines

Optimizing G-Code involves streamlining commands to improve efficiency and reduce machining time. Minimizing unnecessary movements and retractions helps conserve tool life and machine wear. Combining commands where possible reduces line count‚ saving memory on older controllers. Adjusting feed rates and spindle speeds for specific materials ensures optimal performance. Avoiding excessive decimal places in coordinates prevents rounding errors. Using the correct tool paths and avoiding redundant commands enhances accuracy. Including a G-Code list PDF as a reference ensures standardization. These practices ensure smoother operations‚ reduced downtime‚ and higher-quality finishes. Proper optimization is key to achieving consistent and precise CNC machining results.

G-Code Compatibility and Variations

G-Code compatibility varies across CNC controllers due to manufacturer-specific extensions. A G-Code list PDF helps standardize programs‚ ensuring compatibility and optimal performance.

Differences in G-Code Across CNC Controllers

Different CNC controllers interpret G-Code commands uniquely‚ with variations in syntax and functionality. Manufacturers like Fanuc‚ Haas‚ and Heidenhain often add proprietary extensions. A G-Code list PDF highlights these differences‚ ensuring compatibility. While core commands remain consistent‚ parameters and modal codes can vary. For example‚ spindle control (M03/M04) or tool offsets may differ slightly. These variations require programmers to adapt G-Code for specific machines. Using a standardized G-Code list PDF helps bridge these gaps‚ ensuring programs run smoothly across different controllers. This resource is essential for maintaining consistency and avoiding errors in CNC machining operations.

Custom and Extended G-Code Commands

Custom and extended G-Code commands are specialized instructions tailored for specific CNC machines or manufacturers. These commands go beyond standard G-Code‚ offering advanced functionality. For example‚ Fanuc and Siemens controllers often include proprietary codes for unique operations like custom macros or advanced probing. A G-Code list PDF can detail these extended commands‚ helping programmers leverage machine-specific features. While standard G-Code ensures compatibility‚ custom codes optimize performance for particular setups. Programmers must consult the G-Code list PDF for their controller to utilize these commands effectively‚ as they are not universally compatible. These extensions enhance machining capabilities but require precise knowledge for implementation.

A G-Code list PDF serves as a vital reference for CNC machining‚ offering a detailed overview of G-Code commands‚ parameters‚ and syntax. It simplifies programming by providing quick access to essential commands‚ reducing errors and improving efficiency. These PDF resources often include both standard and extended commands‚ ensuring compatibility with various CNC controllers. They are particularly useful for beginners to learn the fundamentals and for experienced programmers to refine their techniques. By organizing commands in a clear format‚ G-Code lists enhance workflow and troubleshooting. They are widely available from manufacturers‚ forums‚ and CNC communities‚ making them an indispensable tool for modern machining operations.

Future of G-Code in CNC Machining

The future of G-Code in CNC machining is poised for advancements driven by technology integration. As CNC machines become more sophisticated‚ G-Code will evolve to incorporate AI‚ machine learning‚ and IoT capabilities‚ enabling smarter‚ adaptive machining processes. The development of custom and extended commands will further enhance functionality. G-Code lists in PDF format will remain essential‚ but they may transition into interactive‚ digital formats for easier accessibility. These resources will likely include real-time simulations and automated error checking‚ streamlining programming workflows. Additionally‚ G-Code will play a key role in Industry 4.0‚ fostering seamless communication between machines and systems. This integration will ensure G-Code remains a cornerstone of CNC machining for years to come.