Allen Key Size Chart PDF⁚ A Comprehensive Guide

This guide provides a comprehensive overview of Allen key sizes and dimensions, with a focus on metric systems. It includes charts and information on various types of Allen keys, their applications, and factors to consider when choosing the right size.

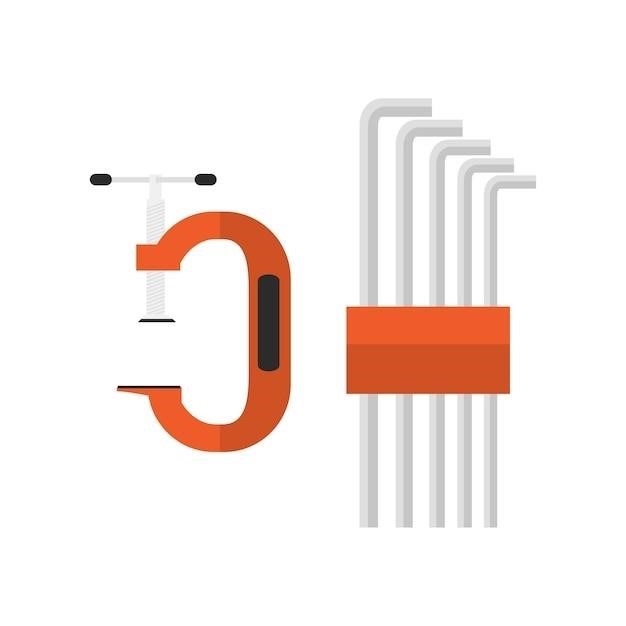

Understanding Allen Keys

Allen keys, also known as hex keys or hex wrenches, are specialized tools designed to tighten and loosen screws with hexagonal sockets. These sockets are recessed into the screw head, providing a secure grip for the Allen key. Unlike traditional screwdrivers, Allen keys utilize a hexagonal shaft that fits perfectly into the socket, ensuring a strong and precise connection.

The unique design of Allen keys offers several advantages over traditional screwdrivers. Their hexagonal shape distributes force evenly across the socket, minimizing the risk of stripping or damaging the screw head. Additionally, Allen keys provide greater leverage and torque, making them ideal for tightening and loosening stubborn or high-torque fasteners.

Allen keys are available in a wide range of sizes, each corresponding to a specific screw socket size. Choosing the correct Allen key size is crucial for ensuring a proper fit and preventing damage to the screw or fastener. Using an Allen key that is too small will result in slippage and potential damage to the screw head, while using a key that is too large can strip the socket or cause excessive force on the screw.

Understanding the different Allen key sizes and their corresponding screw socket sizes is essential for any DIY enthusiast or professional mechanic. This knowledge allows for efficient and effective work, minimizing the risk of damage and ensuring a secure and reliable connection.

Metric Allen Key Sizes and Dimensions

Metric Allen keys are standardized according to the ISO 4762/DIN 912 standards. This ensures consistent sizing and interchangeability between different brands and manufacturers. The key size is represented by the width across the flats (A) of the hexagonal shaft, measured in millimeters. For instance, a 2.5 mm Allen key has a flat-to-flat width of 2.5 millimeters.

Each metric Allen key size corresponds to a specific socket cap screw size. The screw size is indicated by the thread diameter, also measured in millimeters. For example, a M3 screw has a thread diameter of 3 millimeters. The Allen key size required for a particular screw is usually specified by the screw manufacturer or can be found in an Allen key size chart.

In addition to the key size (A), other dimensions relevant to Allen keys include the length (L) of the short arm or long arm, and the shortest length (B). These dimensions are important for selecting the appropriate key for a particular application, considering factors like access space and required torque. The length of the Allen key determines the leverage it provides, while the shortest length ensures a secure grip within the socket.

Understanding the metric Allen key size and dimensions is crucial for selecting the correct key for a particular application. Using the wrong size can lead to stripping the screw head, damaging the Allen key, or applying excessive force on the screw. Therefore, it’s essential to refer to an Allen key size chart or consult the screw manufacturer’s specifications before using an Allen key.

Allen Key Size Chart for Socket Cap Screws

Socket cap screws, also known as hex socket head cap screws, are commonly used fasteners with a hexagonal recessed head. These screws require Allen keys for tightening and loosening. A size chart for Allen keys specifically for socket cap screws is essential for proper installation and removal.

The chart typically lists the screw size (thread diameter) in metric units, ranging from M3 to M24 or larger. Each screw size corresponds to a specific Allen key size, indicated by the width across the flats of the hexagonal shaft. For example, an M3 screw typically requires a 2.5 mm Allen key, while an M10 screw needs a 5 mm Allen key.

The chart also provides dimensions for the Allen keys, such as the length of the short arm and long arm, and the shortest length. These dimensions are important for selecting the appropriate key based on the accessibility of the screw and the desired torque. A longer arm provides more leverage, while a shorter arm is suitable for tight spaces.

The Allen key size chart for socket cap screws is a valuable tool for anyone working with these fasteners. It ensures the correct key size is used for each screw, preventing damage to the screw head, the Allen key, and the workpiece. It also helps ensure that the appropriate torque is applied during installation, preventing over-tightening or loosening.

Allen Key Size Chart for Short Arm and Long Arm Wrenches

Allen keys are available in two primary configurations⁚ short arm and long arm. The choice between these depends on the specific application and the accessibility of the screw. A short arm wrench is ideal for tight spaces where a longer wrench would be impractical. Conversely, a long arm wrench provides increased leverage for tightening or loosening stubborn screws.

An Allen key size chart for short arm and long arm wrenches typically lists the hex key size (width across the flats) in metric units or imperial units. It then provides the corresponding dimensions for both short arm and long arm wrenches. This includes the length of the short arm, the length of the long arm, and the radius of the bend (for long arm wrenches). The chart can also specify the material of the wrench, such as chrome vanadium steel, which is known for its durability and strength.

When selecting an Allen key wrench, it’s crucial to consider both the size and the type of wrench needed. A short arm wrench is often preferred for delicate work and in confined areas, while a long arm wrench offers the advantage of increased torque. The chart helps ensure that the correct tool is chosen for the specific task, enhancing efficiency and minimizing the risk of damage to the screw or the workpiece.

Allen Key Size Chart for SAE and Metric Systems

Allen keys, also known as hex keys, are designed for driving screws with hexagonal sockets. They are available in both SAE (Imperial) and metric sizes. An Allen key size chart for SAE and metric systems provides a convenient reference for matching the correct wrench to the appropriate screw size.

The SAE system, commonly used in the United States, employs fractional measurements like 1/16 inch, 1/8 inch, and so on. Metric sizes, prevalent in most other parts of the world, use millimeter measurements. An Allen key size chart for both SAE and metric systems will typically list the wrench size in both systems, allowing for easy conversion. It may also include the corresponding dimensions of the hex key, such as the width across the flats and the length of the wrench, making it easier to identify the correct size for a specific screw.

It is essential to understand the difference between SAE and metric sizes to avoid using the wrong Allen key. Using the wrong size can damage the screw or the wrench and lead to inaccurate tightening or loosening. A size chart provides a quick and easy way to ensure compatibility between the wrench and the screw, preventing these issues.

Allen Key Size Chart for Torx/Star Keys

While Allen keys are commonly associated with hexagonal sockets, Torx/Star keys are another popular type of wrench for driving screws with a star-shaped recess. These keys, often referred to as “Torx keys,” are characterized by their star-shaped tip, designed to fit into the five-pointed recess of Torx screws.

A dedicated Allen key size chart for Torx/Star keys typically lists the Torx size, often denoted by a “T” followed by a number, such as T10, T15, or T25. The chart may also provide the corresponding dimensions, such as the width across the flats of the key or the overall length.

Torx keys are known for their superior grip and reduced cam-out compared to Allen keys, making them ideal for high-torque applications. They are widely used in various industries, including automotive, aerospace, and electronics. Having a Torx key size chart on hand is crucial for identifying the correct size for the specific Torx screw you are working with, ensuring a secure and efficient tightening or loosening process.

Allen Key Size Chart for Different Screw Types

Allen key size charts are not limited to a single screw type. They can be tailored to encompass various screw types, each requiring a specific Allen key size. For instance, a chart might include socket cap screws, which have a cylindrical head with a hexagonal socket, or set screws, which are typically used for securing components in place.

These charts often categorize screw types based on their head shape, thread size, and material. They may also specify the corresponding Allen key size needed for each screw type. For example, a chart might list the Allen key sizes for M3, M4, and M5 socket cap screws, providing the required key size for each thread diameter.

Having a comprehensive Allen key size chart that covers different screw types is beneficial for both professionals and DIY enthusiasts. It eliminates the guesswork involved in selecting the right Allen key, ensuring a proper fit and preventing damage to the screw head or the wrench. By understanding the relationship between screw types and Allen key sizes, you can work efficiently and effectively with various fasteners.

Allen Key Size Conversion Chart

An Allen key size conversion chart is a valuable tool for anyone working with both metric and imperial systems. It helps bridge the gap between the two systems, allowing you to easily convert Allen key sizes from one system to another. This is particularly useful when dealing with projects or parts that utilize both metric and imperial fasteners.

The chart typically lists common Allen key sizes in millimeters (metric) and their corresponding equivalent sizes in inches (imperial); It often includes both fractional and decimal inch values, making it easier to find the right Allen key regardless of the measurement system used.

For example, a conversion chart might show that a 4 mm Allen key is equivalent to a 5/32-inch Allen key. This allows you to use either metric or imperial wrenches interchangeably, depending on the available tools and the specific project requirements. Using a conversion chart ensures accuracy and prevents the frustration of trying to find the right size wrench when dealing with mixed measurement systems.

Common Allen Key Sizes

A comprehensive Allen key size chart will list the most frequently encountered sizes in both metric and imperial systems. These sizes are commonly used in various applications and are readily available in most tool sets and hardware stores.

Common metric sizes include 1.5 mm, 2 mm, 2.5 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, and 10 mm. These sizes are often found in electronics, furniture assembly, and general DIY projects.

In imperial systems, common sizes include 1/16 inch, 5/64 inch, 3/32 inch, 1/8 inch, 5/32 inch, 3/16 inch, 7/32 inch, 1/4 inch, 5/16 inch, 3/8 inch, 7/16 inch, 1/2 inch, and 5/8 inch. These sizes are often used in automotive, construction, and industrial applications.

While these are common sizes, it is essential to consult a comprehensive Allen key size chart to determine the exact size required for specific screws or bolts. A chart will provide accurate information on the corresponding sizes for various types of fasteners, ensuring proper fit and preventing damage to the fastener or the tool.

Factors to Consider When Choosing an Allen Key

Selecting the right Allen key for a specific task involves considering several factors that ensure optimal performance, prevent damage to the fastener, and provide a secure fit. Here are key elements to consider⁚

Screw Size⁚ The most crucial factor is the size of the screw or bolt. A chart will match the Allen key size to the corresponding screw size, ensuring proper fit and preventing stripping or damage to the fastener.

Material and Strength⁚ The material of the Allen key impacts its durability and ability to withstand torque. For heavy-duty applications, choose a key made from high-quality steel or chrome vanadium steel, known for their strength and resistance to wear.

Length⁚ The length of the Allen key is important for accessibility and leverage. Shorter keys are ideal for tight spaces, while longer keys provide greater leverage when working with larger or more stubborn fasteners.

Type⁚ The Allen key type, including short arm, long arm, and L-shaped variations, impacts its functionality and ease of use. Short arm keys are suitable for general tasks, while long arm keys provide greater leverage for difficult screws. L-shaped keys are handy for tight spaces and offer a greater degree of control;

Purpose⁚ The intended use of the Allen key should be considered. For delicate work, choose a precision Allen key, while for heavy-duty tasks, a standard Allen key is sufficient.

Where to Find Allen Key Size Charts

Accessing reliable Allen key size charts is essential for successful projects, ensuring the correct fit and preventing damage to fasteners. Fortunately, various resources provide readily available information. Here are some common avenues for finding Allen key size charts⁚

Online Resources⁚ The internet offers a wealth of Allen key size charts. Websites specializing in tools, fasteners, and DIY projects often feature comprehensive charts that cover metric, SAE, and other systems. Searching terms like “Allen key size chart PDF” or “hex key size chart” can yield numerous results.

Tool Manufacturer Websites⁚ Reputable tool manufacturers, such as Klein Tools, Truini, and RS PRO, provide detailed charts on their websites. These charts typically include information on their specific Allen key sets, offering a valuable resource for users of their products.

Hardware Stores and Online Retailers⁚ Hardware stores and online retailers like Fastener Express frequently offer Allen key size charts in their catalogs or on their websites. These charts can be helpful for finding specific sizes or comparing different Allen key sets.

Engineering and Mechanical Handbooks⁚ Engineering and mechanical handbooks often include sections on fasteners and tools, providing comprehensive Allen key size charts and other relevant technical information.